There is a lot of chatter in the bubblesphere about how to repair bubbles. For over a year now, we’ve done more than our share of R&D on glues, patches, goops, and tapes. And we’re still doing research.

For fast (but temporary) keep-it-in-the-game patches, there’s nothing better than this tape.

For fast but permanent repairs to small tears and holes that you can fix in the field before or after an event, Tear-Aid products work well.

The Problem

The perennial question continues to be asked by bubble businesses everywhere: Should I use Tear-Aid A or Tear-Aid B? And should I choose differently for TPU and PVC?

From what we understand, the Tear-Aid folks themselves recommend the B-variety for PVC, which makes sense, because PVC is vinyl, the target surface of B-variety. We haven’t heard directly from them regarding what to use with TPU.

The bubble community around the world has mixed opinions. Some swear by A, some swear by B. Some are fixing TPU. Some are fixing PVC.

We decided to get to the bottom of it once and for all.

The Science

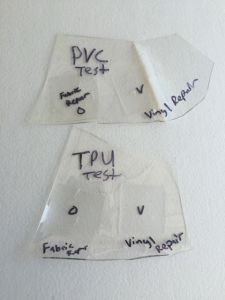

We applied patches of both A and B to both PVC and TPU and left them for 24 hours, and then pulled them apart to see how well all combinations adhered. (For good measure, we also stuck both varieties to the clear, rope-anchor circles on the bubbles, since we aren’t sure what those are made of, and we’ve had trouble getting patches to stay stuck to them in the past.)

The Results

Inconclusive! Uggghhh. Well, we do have a preference, but there wasn’t a clear winner.

On both TPU and PVC, both A and B varieties adhered pretty well. It was hard to tell any difference in how well they stuck. The difference was that, on both surfaces, B-variety comes off cleanly, without mess, and A-variety comes off goopy and kind of messy, leaving a sticky residue behind on the surface.

What does this mean for us bubblers? The good news is, you’re probably ok using either variety on either surface. It occurs to us that the gooey-ness of A-variety might be an advantage, because it might help get down into crannies between seams and keep air from sneaking out. On the other hand, B-variety is much cleaner to remove if you should need to re-patch the area.

We’ve decided for now to stick with B-variety for both surfaces, which is what we have been using.

Regardless of whether you use Tear-Aid A or Tear-Aid B, we recommend applying a double-layer patch, with the bottom patch being more than completely covered by the top one on all sides. We’ll try to post a video of our technique one of these days.